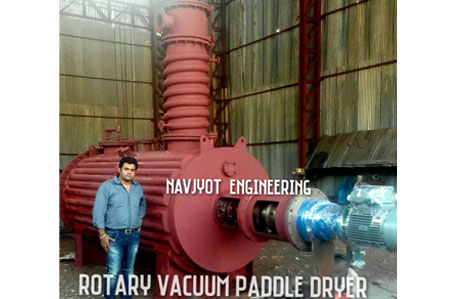

Rotary Vacuum Paddle Dryer - RVPD

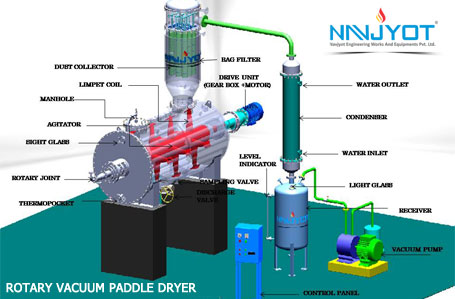

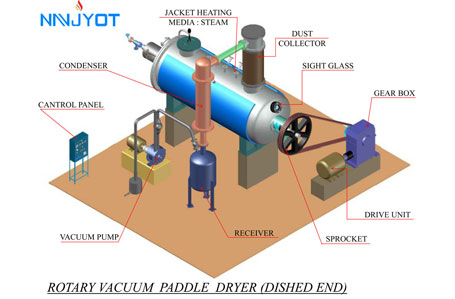

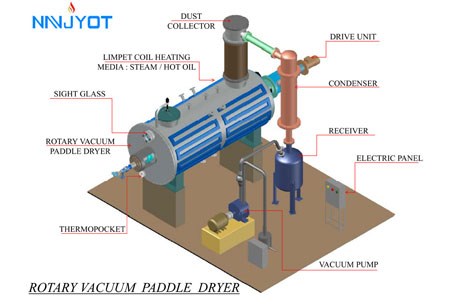

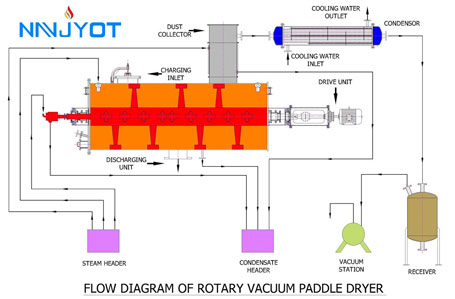

- Comprising of horizontal cylindrical shell with suitable ends, slow speed paddle agitator is designed for mixing, drying and discharging the products.

- This is used for making powder from wet cake or slurries, in batch type operation often under vacuum.

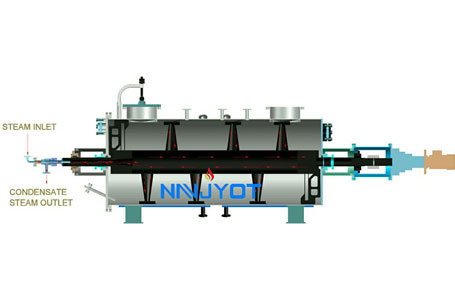

- Product is heated from outside through shell ends and from inside through shaft paddles, by means of steam or hot oils.

- Product filter, condenser, receiver and vacuum system are part of the drying operation.

- Optional mechanical chopper cum de-agglomerater can be provided for breaking lumps formed while drying.

Features:

- Externally heated through jacket/limpet coils.

- Internally heated agitator shaft for maximum heat transfer area.

- Dries and conveys for discharge.

- Efficient rotary joint to inject heating media into agitator and remove condensate.

- Pre-piped with heating medium inlet to dryer and condensate out to headers.

- Quick opening manual discharge valve and charging door for minimum manual handling.

- Chain sprocket drive through speed reducers and motor

- Direct drive through speed reduced motor.

- Control panel totally pre-wired for ease of performance taking into account safety factors

TECHNICAL SPECIFICATION:

| MODEL | NEWRVPD 500 | NEWRVPD 750 | NEWRVPD 1000 | NEWRVPD 1500 | NEWRVPD 2000 | NEWRVPD 3000 | NEWRVPD 4000 | NEWRVPD 5000 |

|---|---|---|---|---|---|---|---|---|

| Total Volume in Ltrs | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

| Working Volume in Ltrs | 300 | 450 | 600 | 900 | 1200 | 1800 | 2400 | 3000 |

| Capacity in Kg (max) | 175 | 250 | 350 | 500 | 700 | 1000 | 1350 | 1700 |

| Shell Dia mm | 650 | 725 | 800 | 900 | 1000 | 1100 | 1250 | 1250 |

| Shell Lenth mm | 1500 | 2000 | 2000 | 2350 | 2600 | 3200 | 3300 | 3500 |

| RPM of Paddle | 14 | 12 | 10 | 10 | 8 | 8 | 8 | 8 |

| Heat transfer area in m2 | 4 | 5 | 7.5 | 9 | 10 | 14 | 17 | 20 |

| Dust Filter Area m2 | 0.25 | 0.35 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 1.75 |

| Condenser in m2 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4 | 4 |

| Receiver in Ltrs | 75 | 100 | 150 | 200 | 250 | 250 | 250 | 250 |

| Charging Ht in mm | 1650 | 1750 | 1900 | 2200 | 2300 | 2400 | 2600 | 2800 |

| Discharging Ht in mm | 650 | 650 | 750 | 750 | 750 | 750 | 750 | 750 |

| Charging Size in mm | Φ100 | Φ100 | Φ125 | Φ125 | Φ150 | Φ500 | Φ200 | Φ200 |

| Discharging Size in mm | Φ150 | Φ175 | Φ200 | Φ200 | Φ250 | Φ250 | Φ300 | Φ300 |

| Gear Box | 4 " | 4 " | 5 " | 5 " | 6 " | 7 " | 8 " | 10 " |

| Main drive motor | 5HP | 5HP | 7.5HP | 7.5HP | 10 | 15 | 20 | 25 |

| Length in mm | 2900 | 3350 | 3750 | 4350 | 4750 | 5250 | 5500 | 5750 |

| Width In mm | 950 | 1050 | 1125 | 1200 | 1325 | 1500 | 1625 | 1700 |

| Height in mm | 2200 | 2500 | 2850 | 3000 | 3250 | 3700 | 3800 | 4000 |

| Weight in Kg (Aprox) | 800 | 1000 | 1250 | 1500 | 1900 | 2500 | 3000 | 3500 |